PatchPals

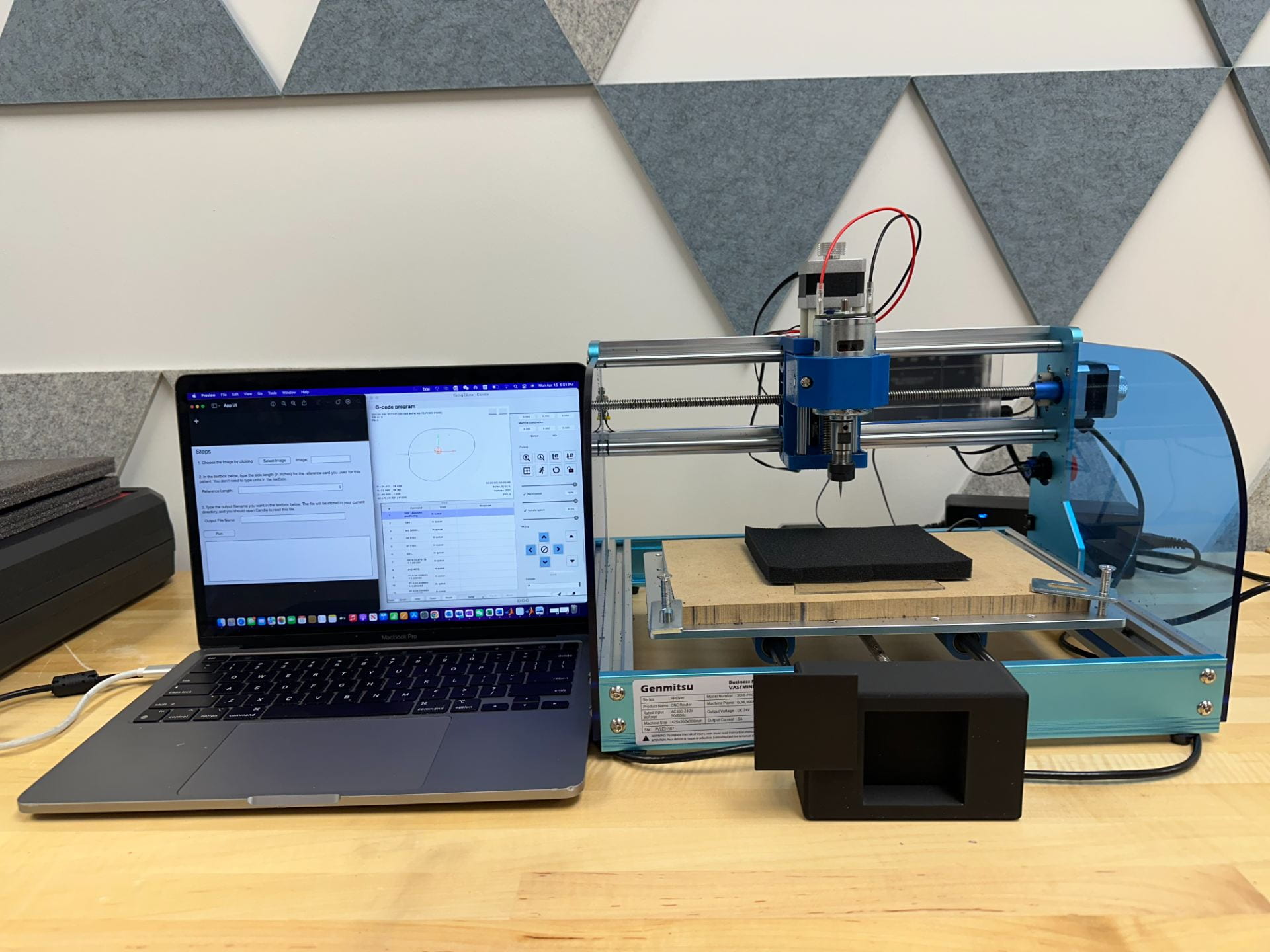

Streamlined negative pressure setup through wound image segmentation and CNC foam cutting

Project Description:

Negative Pressure Wound Therapy Devices (NPWT) are applied to chronic or non-healing wounds to promote granulation tissue growth. These devices work by manually cutting and fitting a piece of polyurethane foam inside the wound bet, sealing it with an adhesive drape and tubing, and administering negative pressure. The foam is critical to distribute the pressure uniformly, but the foam-cutting process is time consuming. Wound care nurses reported that the most time limiting step of the wound dressing changes was the foam-cutting, causing the total time of a dressing change to take up to 90 minutes. Our device remedies this issue by reducing the time it takes to change wound NPWT dressings. Nurses simply take a photo of the wound, outline it, and pass the marked-up image through our software. The software scales the wound and generates cutting instructions for a CNC machine, which will cut the foam in the precise shape of the wound. Our device requires less than one minute of “hands-on” time, cutting the total dressing change time by 23%. Additionally, our device is tested with 93% accuracy with respect to the wound’s dimensions. With this device, nurses not only save time by avoiding the time-consuming and trial-and-error based foam-cutting process but are also able to prepare other components of the dressing change while the foam is being cut for them.