Joint Effort

Elbow Replacement Alternative to Reduce Loosening and Treat Severe Distal Humerus Fractures

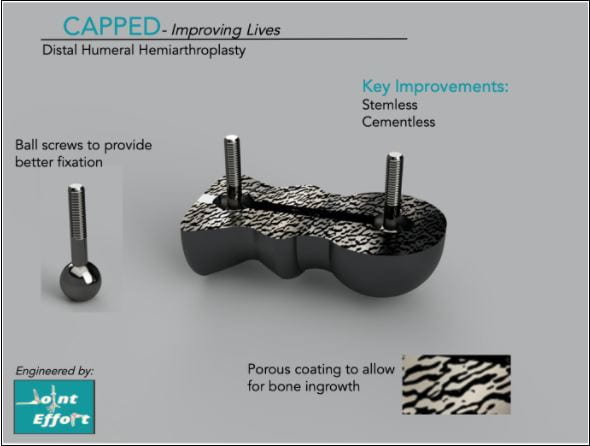

Ball and socket design for the screws that allows the surgeon to maneuver the angle of the screws themselves and lock “Capped” in place. This implant replaces the surface of the joint on the distal humerus to treat fractures in that location as an affordable, cementless, and less-invasive alternative to replacing the entire elbow joint.